Blackadder

New member

Years ago when my son first acquainted me with the Warhammer phenomenon he showed me a catalog of the FW products. Having been in the Service I had an awe of the mechanized armour although even then I knew

"A moving foxhole attracts the eye."

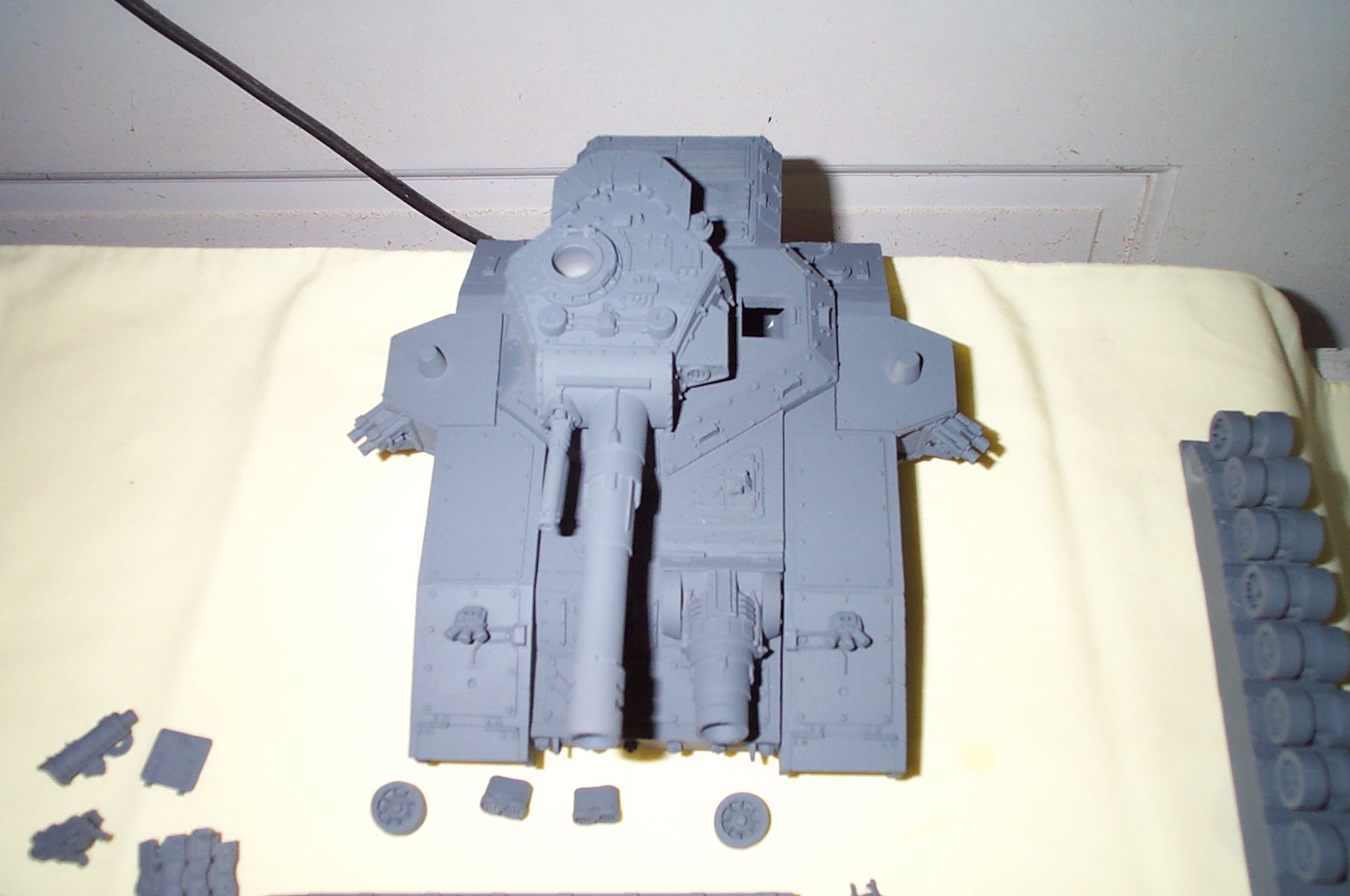

Anyway I fell in love with the anachronistic clanking abomination known as the Baneblade Super-heavy Tank. Not just the Baneblade but the Lucius Pattern version to be precise with looks even more archaic than the Mars Pattern.

Reading the spec's on this behemoth Gad 316 tonnes! 13.5 metres long 6.3 metres high that's literally as big as my house was at that time.

Then and there I resolved to get one of those vehicles but the FW price was prohibitive. What to do? well there was ebay, you can find anything for sale on ebay so I gave that a try.........

After a few days a Lucius Baneblade showed up.............

http://i.imgur.com/2cM66kT.jpg

and I watched it count down the days to the final few seconds and at the last moment I dumped in my bid. Walla (sic) I won the bid! I forgot what I paid for it but I'm sure it was way too much but still a heck of a lot cheaper than a new one from Forge World..........

Watching the post regularly it ultimately arrived; Whoa what a piece of junk! It looked even worse than it appeared in the ebay picture Caveat emptor!

http://i.imgur.com/NLcS2Az.jpg

http://i.imgur.com/sMkgoDh.jpg

of course I knew that the thing was assembled badly but I was pretty sure I could restore it to a semblance of its potential glory.

"A moving foxhole attracts the eye."

Anyway I fell in love with the anachronistic clanking abomination known as the Baneblade Super-heavy Tank. Not just the Baneblade but the Lucius Pattern version to be precise with looks even more archaic than the Mars Pattern.

Reading the spec's on this behemoth Gad 316 tonnes! 13.5 metres long 6.3 metres high that's literally as big as my house was at that time.

Then and there I resolved to get one of those vehicles but the FW price was prohibitive. What to do? well there was ebay, you can find anything for sale on ebay so I gave that a try.........

After a few days a Lucius Baneblade showed up.............

http://i.imgur.com/2cM66kT.jpg

and I watched it count down the days to the final few seconds and at the last moment I dumped in my bid. Walla (sic) I won the bid! I forgot what I paid for it but I'm sure it was way too much but still a heck of a lot cheaper than a new one from Forge World..........

Watching the post regularly it ultimately arrived; Whoa what a piece of junk! It looked even worse than it appeared in the ebay picture Caveat emptor!

http://i.imgur.com/NLcS2Az.jpg

http://i.imgur.com/sMkgoDh.jpg

of course I knew that the thing was assembled badly but I was pretty sure I could restore it to a semblance of its potential glory.

Last edited: